6.9 Phyto-mediated Wastewater Treatment for Removing Contaminants from Wastewater Effluent

By Matt Recsetar, Assistant Research Professor, Department of Biosystems Engineering, University of Arizona

Joel Cuello, Professor Department of Biosystems Engineering, University of Arizona

A case study for using a recirculating hydroponic bioreactor to remove contaminants of emerging concern from Arizona wastewater effluent.

At least 45 contaminants of emerging concern (CECs) have been detected in tertiary treated wastewater effluent in Tucson, Arizona. These contaminants, ranging from pharmaceutical compounds and personal care products (PPCPs) to disinfection byproducts, household chemicals and various endocrine disrupting compounds (EDCs), are not currently regulated by the EPA. Little is known about the long-term effects of these contaminants but studies have already shown negative effects on aquatic organisms (Ashton et al., 2004; Gomes et al., 2003; Kostich et al., 2014). Since these compounds are not always fully removed through the current wastewater treatment process, many of them ultimately end up in drinking-water aquifers as the effluent is recharged into the ground. While they may not be detectable in drinking water quite yet due to dilution effects and limits of detection of sensor or instrument used, it is only a matter of time before they start showing up.

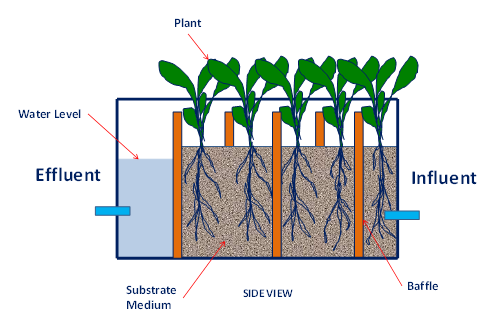

With the circular bioeconomy in mind, Drs. Recsetar and Cuello of the Department of Biosystems Engineering designed a scalable strategy to treat wastewater effluent without generating additional waste and to produce an effluent that could be safe for human use and consumption. The solution designed incorporates the phytoremediation capabilities of plants into a novel patent-pending scalable bioreactor (Figure 1). While the foregoing contaminants could be removed with expensive filtration techniques such as reverse osmosis or carbon filtration, these methods still create an additional waste stream which will ultimately end up in a landfill and not foster a circular bioeconomy (Ghosh and Singh, 2005; Le-Minh et al., 2010; Verlicchi and Zambello, 2014). Constructed wetlands, which provided inspiration to our patent-pending hydroponic bioreactor, have been around for dozens of years to treat wastewater effluent. Further, they have been shown to aid in the removal of many of the contaminants of emerging concern through various processes that do not occur in wastewater treatment plants (Ávila et al., 2014; Bhatia and Goyal, 2014; Maine et al., 2007; Özengin and Elmaci, 2016; Verlicchi and Zambello, 2014). Plants, for instance, have been shown to take up contaminants such as pharmaceutical compounds and break them down internally through a process called phytodegradation.

Figure 1. Side-view schematic of the scalable Phyto-Mediated Wastewater Treatment Bioreactor (PWBR) equipped with baffles serving as flow guides to optimize contact between the flowing influent and the plant roots in the substrate (Recsetar and Cuello. 2022).

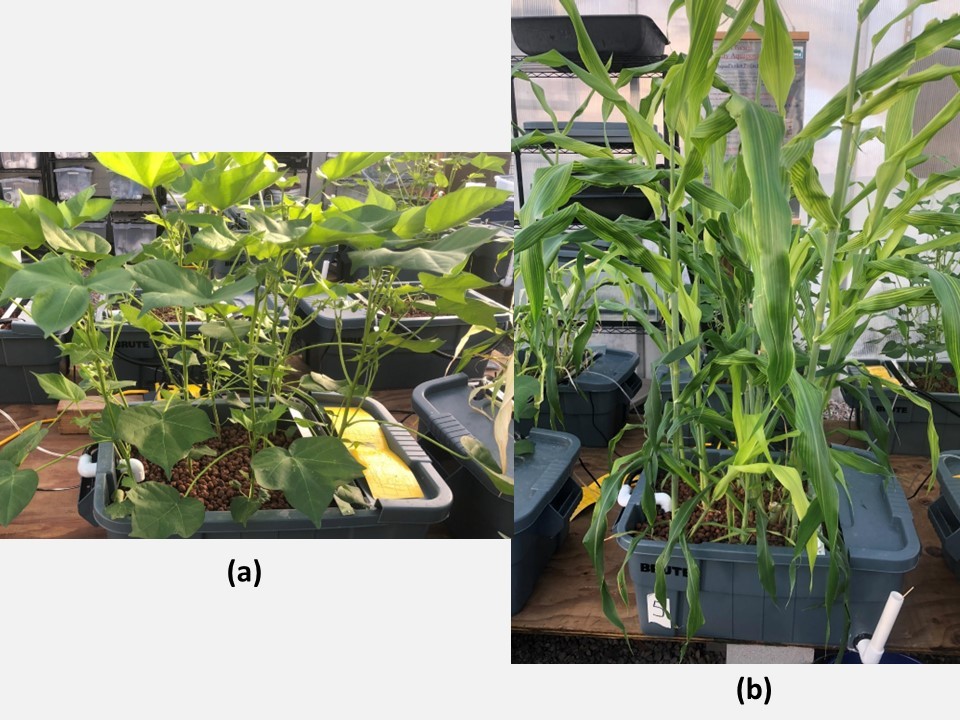

The treatment capacity and effectiveness of our patent-pending recirculating Phyto-mediated Wastewater Treatment Reactor (PWBR) to remove CEC’s from wastewater (Recsetar and Cuello. 2022) was investigated using switch grass, cotton and sorghum growing in a substrate of light expanded clay aggregate (LECA) (Recsetar et. al., 2021) (Figure 2) in a greenhouse at the University of Arizona Controlled Environment Agriculture Center (CEAC).

FIGURE 2. EXPERIMENTAL BENCHTOP EMBODIMENTS OF THE PWBR WITH COTTON (GOSSYPIUM ARBORETUM) (A) AND SORGHUM (SORGHUM BICOLOR –CAÑA GANCHADO) (B).

Atenolol, Benzotriazole, Carbamazepine, Hydrochlorothiazide, Iohexol, Iopamidol, Iopromide, Primidone, sulfamethoxazole and Tris (chloropropyl) phosphate (TCPP) were reduced by greater than 80% in all treatments, while the control exhibited little to no removal after 5 days. Indeed, almost every contaminant initially present in the effluent was reduced below detection limits or by >90%. The cotton plants specifically appeared to have been especially effective in treating pharmaceutical compounds, while a combination of the clay substrate and microbiome contributed to reducing the other types of compounds. We believe that industrial hemp could be another valuable industrial crop that would perform effectively in this bioreactor. Thus, the scalable PWBR may be licensed to treat any effluent that contains contaminants of emerging concern that would otherwise enter the environment.

Agricultural applications for PWBR. The PWBR (Recsetar and Cuello. 2022) could be deployed to provide safe water for human use as well as clean water supply for agriculture or aquaculture in various parts of the world. In addition, this technology has applications in arid lands where clean water is a scarce resource. It could also be utilized to treat agricultural effluent from dairy farms, swine farms, or other livestock operations. Further, this scalable technology is relatively low-cost and could have applications in any industry that produces effluent that is not potable and requiring treatment of large batches of water for use in agriculture or aquaculture.

PWBR for Circularity. Treating wastewater effluent using the scalable PWBR has the potential to remove contaminants from our future water supply and produce valuable plant byproducts that can be used to make fibers, concrete, and myriad other industrial products. The PWBR innovation can effectively close the loop on our water use and reuse cycle and has the potential to protect our valuable water supply for years to come.