6.6 Underground Vertical Farming in Southern Arizona as Inspired by Underground Vertical Farming on the Moon and Mars

By Joel L. Cuello, Professor, Department of Biosystems Engineering, University of Arizona

Current research and engineering innovations for underground vertical farming in southern Arizona to be linked with external bioeconomy nodes to achieve circularity.

Southern Arizona represents a competitive location for the establishment of an urban/peri-urban vertical-farming industry (Cuello, 2014; Cuello, 2018) in view of the availability and relatively low cost of land as well as the year-round abundance of solar radiation, among others. A significant disadvantage, however, is its appreciable temperature swings between seasons in a given year.

The hot season in Tucson lasts on average for 3.7 months, from May 25 to September 17, with an average daily high temperature exceeding 34°C (94°F). July is the hottest month of the year in Tucson, with an average high of 38°C (100°F) and low of 25°C (77°F). The cool season, contrastively, lasts for 3.2 months, from November 22 to February 28, with an average daily high temperature below 22°C (72°F). December is the coldest month of the year in Tucson, with an average low of 6°C (43°F) and high of 19°C (66°F) (weatherspark, 2023).

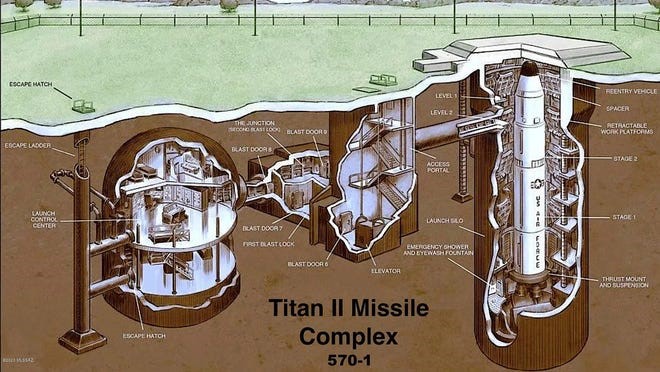

Incidentally, southern Arizona is home to underground silos that were built for the Cold War’s Titan II missile program, which began in 1963 and was decommissioned in the 1980s. The U.S. once operated more than 50 Titan II missile sites across the country, and 18 of them are located in southern Arizona (Figure 1). Most of these underground silos have been purchased by private buyers. In 2019, an underground Titan missile silo site east of Picacho Peak was sold, and in 2020 a former missile complex in Oracle, northeast of Tucson, and of a silo in Benson, southeast of Tucson, were listed for sale (Reagor, 2020). Potential buyers cited various reasons for acquiring the silos, which included converting them into a medical marijuana production facility (Reagor, 2020). A significant advantage of these southern Arizona underground silos, or of underground facilities in general, is their natural capacity to maintain lower and very stable ambient temperature year-round compared with facilities located on the surface.

Figure 1. Titan II missile complex in southern Arizona showing underground silos (Reagor, 2020).

The concept of an underground vertical farm has already been commercially realized, with the first case attributed to that for Zero Carbon Farms in London, U.K. that makes use of a former government-built World War II underground shelter located at 33 meters deep under southwest London (Broom, 2021). The vertical farming company owns a hectare of underground growing space producing greens, including Thai basil, garlic chives and pea shoots (Broom, 2021).The University of Arizona Biosystems Engineering Laboratory in the Department of Biosystems Engineering had designed and operated a NASA-sponsored Subterranean Plant Growth Facility (SPGF) (Cuello et al., 2000; Cuello et al., 2001) that used above-ground solar concentrators which collected and concentrated solar irradiance for conveyance through fiberoptic cables to provide solar lighting -- in hybrid combination with electric lighting, such as LEDs -- to crops grown in underground controlled-environment growth chambers (Figure 2).

Figure 2. The University of Arizona NASA-sponsored Subterranean Plant Growth Facility (SPGF) equipped with above-ground solar concentrators for collection and conveyance of solar irradiance through fiberoptic cables to provide solar lighting -- in hybrid combination with electric lighting, such as LEDs -- to crops grown in underground controlled-environment growth chambers.

Meanwhile, with reinvigorated commitment to space exploration that includes long-duration crewed missions on the Moon, Mars and beyond, a handful of national space programs such as NASA in close cooperation with private aerospace companies – including SpaceX, Blue Origin, Virgin Galactic, NanoRacks, Voyager Space, Lockheed Martin, Sierra Space and Bigelow Aerospace, among others -- are currently developing the necessary innovations in the service of such missions, including innovations for food production in the extraterrestrial environment.

Long-duration crewed missions on the Moon, Mars and beyond require sustainable and resilient life support systems, including bioregenerative life support systems that encompass food crop production by way of engineered controlled environment. The crops serve as food for astronauts, and crop production itself can play key roles in air regeneration and water purification and reuse within an extraterrestrial human habitat.

A significant limitation in growing crops in an extraterrestrial environment is its extreme environment that is simply fatal to biological organisms. In addition to the lack of available flowing water and arable land, the surfaces of the Moon and Mars are constantly exposed to ionizing radiation, bombarded by meteors and micrometeorites, often plagued by gigantic dust storms, and regularly treated to wild diurnal swings in ambient temperature. Thus, the processes of erecting, building, operating and maintaining structures on the surfaces of the Moon and Mars are replete with challenges, not the least of which is the requirement for special materials that possess both significant mechanical strength and durability and the ability to withstand sustained exposures to extreme radiation, repetitive and large thermal fluctuations, and frequent pounding by micrometeorites and dust storms.

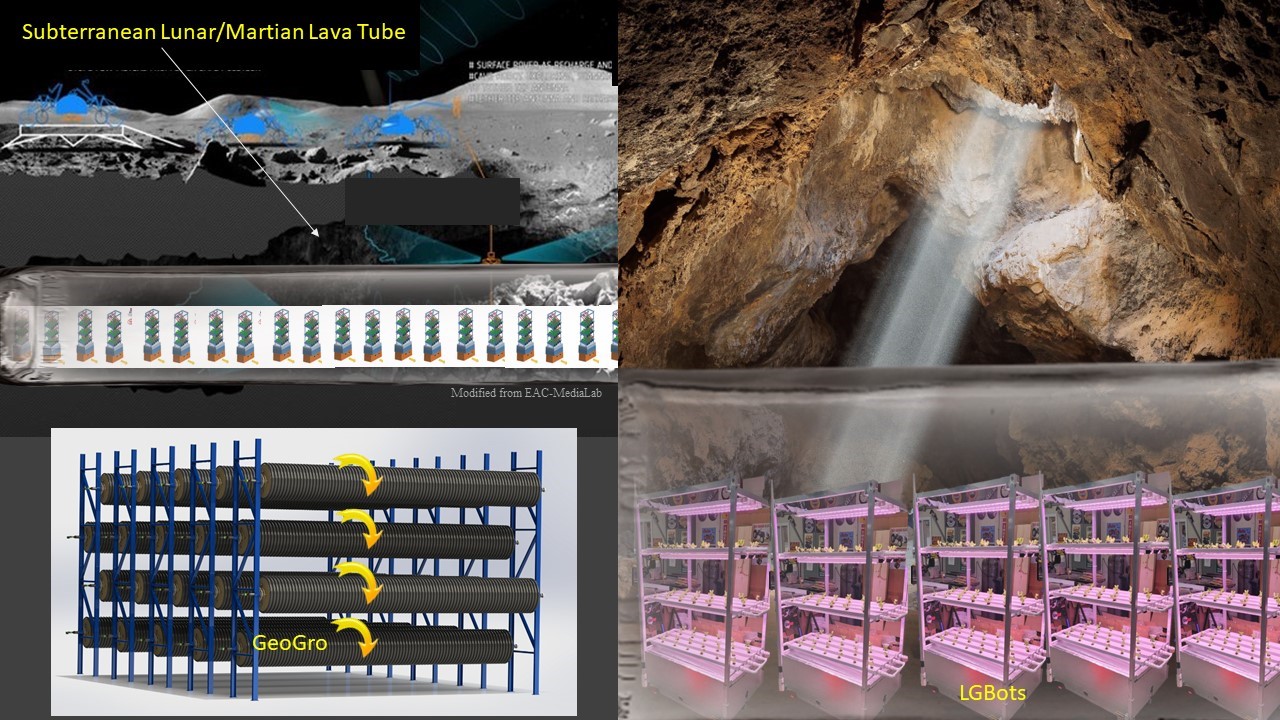

To this end, the Biosystems Engineering Laboratory – in partnership with external experts, i.e., structural and systems engineer Matteo Pietrobelli and vertical farming entrepreneur Mackenze McAleer – has designed the patent-pending BORING (BurrOwing & Regenerative IN-Ground) Vertical Farm. The BORING Vertical Farm is characterized by its embedded location in subterranean spaces, such as lava tubes, beneath the surface of the Moon and Mars, and was conceived and designed to enable the productive growth of crops in space for long-duration and permanent human habitation (Cuello et al. 2022) (Figure 3).

A preferred embodiment of the BORING Vertical Farm is one comprising an inflatable chamber or group of chambers using materials such as rigidized gossamer structures, thermally cured thermoset composites, metamaterials, annular foam-rigidized structures or aluminum and film laminates.

The crop growing systems to be used in a BORING Vertical Farm may be any of or modifications of existing growing systems that have, for instance, been developed and demonstrated for the International Space Station. Two preferred novel embodiments include the mobile and modular LifeGrow Bots (LG Bots), a patent-pending innovation by the Biosystems Engineering Laboratory, and the soil-based GeoGro, a patented innovation by M. McAleer (Figure 3).

The BORING Vertical Farm, in whole or in part, serves to directly inform design embodiments of underground vertical farms for southern Arizona.

Figure 3. Depiction of embodiments of the patent-pending BORING (BurrOwing & Regenerative IN-Ground) Vertical Farm, characterized by its embedded location in subterranean spaces, such as lava tubes, beneath the Lunar or Martian surface and designed to enable productive growth of crops in space for long-duration human habitation. Examples of its crop growing systems include the mobile and modular LifeGrow Bots (LG Bots), a patent-pending innovation by the Biosystems Engineering Laboratory, and the soil-based GeoGro, a patented innovation by M. McAleer.

Underground vertical farms in southern Arizona could be linked with external bioeconomy nodes to achieve circularity (Table 1). Potential input feed could come from external industry nodes, including electric power plants, greenhouses, open-field agriculture, aquaculture operations, and food and beverage manufacturing facilities, among others.

Table 1. Underground vertical farms in southern Arizona for scaled-up production of vegetables, fruit berries, herbs and microgreens, among others